Covid-19: MIT launches 2D cut, one-piece face shield

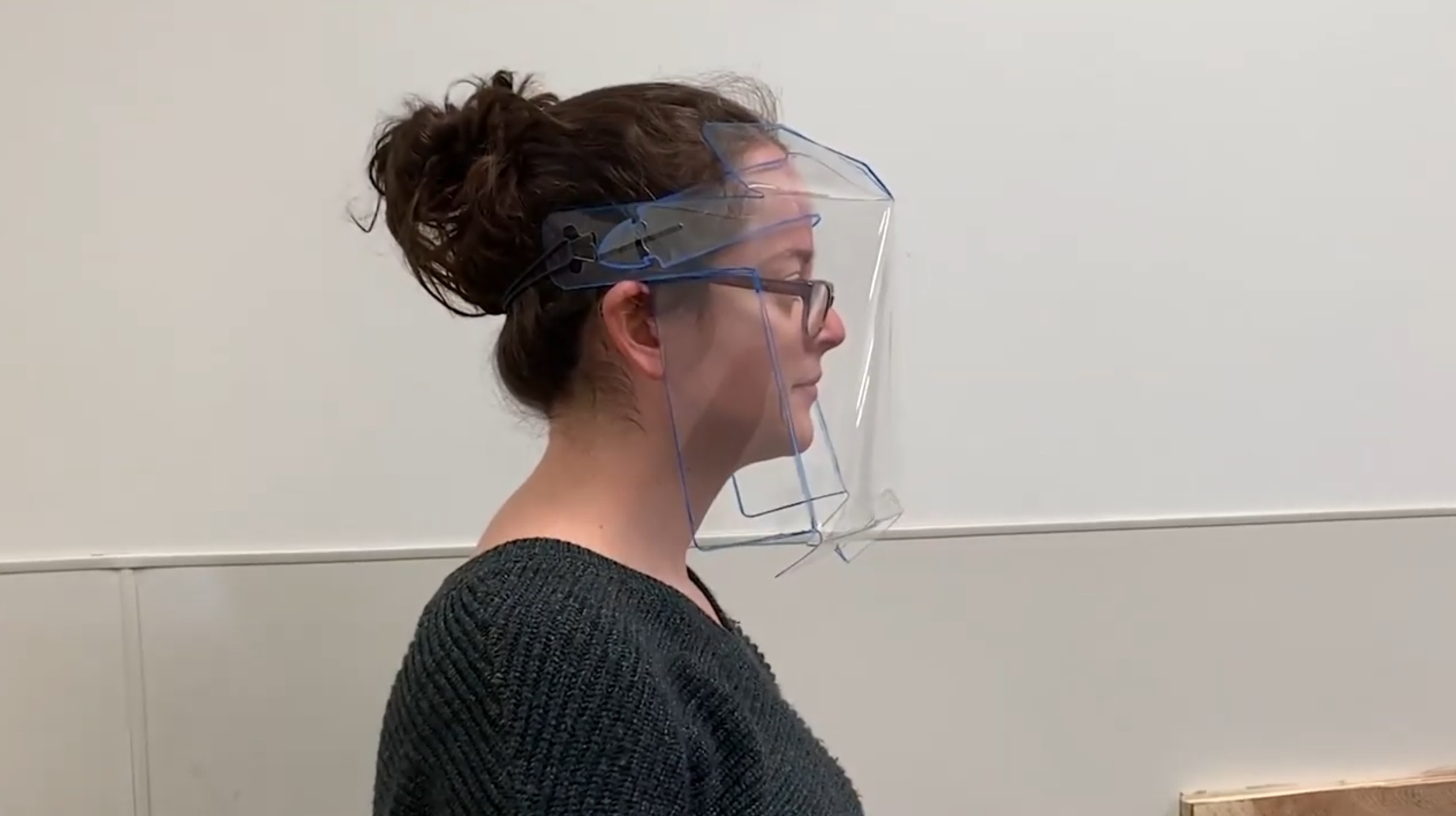

MIT’s Project Magnus has designed a model for a complete face shield that can be cut out in one (foldable) piece from a single flat sheet. According to the website the shields are fabricated using a digital die-cutting machine (Zünd brand, for example) to make cuts and creases on a single sheet of plastic that can then be folded into a three-dimensional face shield. Project Magnus estimates that, thanks to this all-in-one 2D design, more than 2.5 million shields could be printed in a single week.

For now the file is reserved for professional manufacturers that can produce at least 4,000 units per day. Each shield can be cut in 1.5 minutes and assembled by hand in less than a minute, then dropped off directly at hospitals. Nurses and doctors can also assemble them on site if necessary. Unfolding the shield into a flat sheet after use might also make it easier to disinfect, and therefore be reused.

Romain di Vozzo, of Fablab Digiscope at Paris-Saclay University, explains: “This origami design is particularly interesting because it’s all-in-one piece, two-dimensional before assembly, easy to store and flexible. It should be possible to disinfect and reuse for several cycles if it’s cut from an adequate material with sufficient thickness. PETG seems like a good material for these shields. As early as the second week of lockdown in Paris, we were able to locate a PETG reseller, despite the increasing difficulty in sourcing digital fabrication materials (3D printing filament, flexible fabrics, 200+ micron transparent plastics). Fablab Digiscope was able to acquire more than 50m2 of PETG at a thickness of 0.75mm so that we could go from 3D-printing headbands—a lengthy process in terms of fabrication time—to 2D cutting, either by die-cut or laser, whole face shields as soon as possible. The material should be delivered next Monday. We hope to produce approximately 2,500 units, thanks to the university’s distributed network of digital fabrication laboratories.”

Assembly instructions:

More on the all-in-one face shield model by Project Magnus at MIT.